On the left is a stack of regular Petit Lulu diapers, on the right the Fluffy Organic version that does not contain any polyester.

A frequently heard reason for (starting to) use reusable diapers is 'sustainability'. But what exactly is sustainability? And is one diaper actually more sustainable than the other diaper?

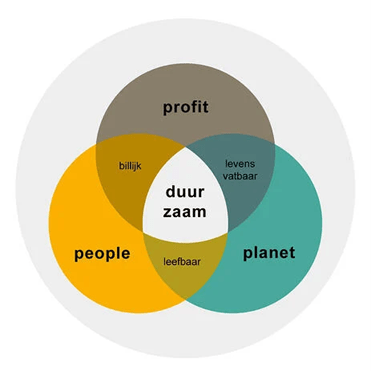

The term 'sustainability' has several definitions. A commonly used definition is that of the three Ps; People, Planet and Profit must be in balance with each other. If all three conditions are met, you can call it sustainable.

Sustainability: People, Planet and Profit must be in balance

In general, you could say that a sustainable product during its lifecycle from production to processing (as waste) is not detrimental to the big picture.

In addition to the above definition of sustainability, there is also a second kind of sustainability; durability. Durability is mainly about how long an product will last before it needs to be replaced. Ideally, a product naturally meets both definitions of sustainability. There are produced sustainably with an eye for People, Planet and Profit and lasts as long as possible.

Sustainability is an important concept in the reusable cloth diaper world. In fact, many of us use reusable diapers mainly because it is a sustainable product. But one diaper is of course even more durable than the other diaper, although a very factual reasoning in this is difficult.

The P from People

Fun in the workplace is very important; how high can we get this stack of diapers?

If we look at the first P of People, then it is about taking care of all people in the chain as best as possible. From the grower of the bamboo, cotton and hemp to the web shop employee who packs the order and the parcel deliverer who delivers the package. The growers, production employees and transporters from the production location to the store are therefore diaper dependent. As a seller you have only a minor influence on this. Of course you look for a brand and you don't add a brand where you suspect that the employees in the chain are not well taken care of, but exercising substantive influence is often quite a challenge. Consciously choosing brands produced as sustainably as possible is therefore a very important part of sustainable business operations.

As a company, you also have a major influence on taking good care of your own employees. A fair wage, pleasant working conditions, a good atmosphere and reasonable working hours are important aspects of this. And cake and chocolate of course!

The P for Planet

Reusable diapers are made of various materials. Bamboo, (organic) cotton and hemp are the most commonly used natural materials. Tencel is also becoming more common. The synthetic fiber polyester is often used to support a natural material, although there are also diapers made entirely of polyester. People often tend to find a natural material better or more durable than a synthetic fiber. But in fact this is very complicated.

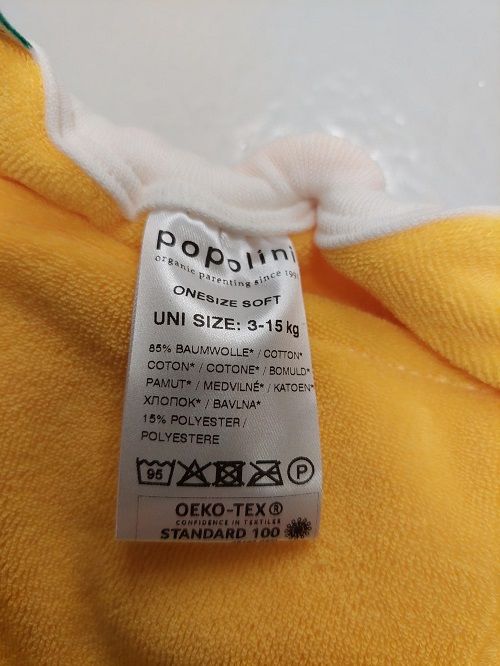

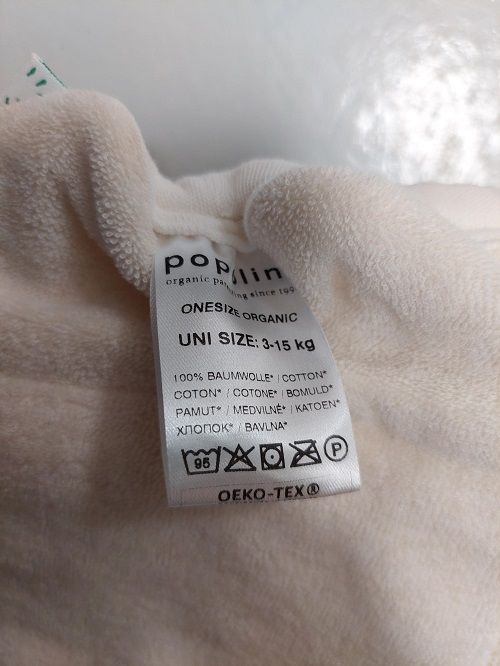

Material Composition of two different diapers. The yellow diaper is a mix of organic cotton and polyester, the white diaper is made of 100% organic cotton.

Bamboo

Bamboo is very popular both for use in clothing and diapers. A major advantage compared to growing cotton is the lower water consumption and the amount of land required. Per m2 of lang, the yield of bamboo is 10x higher than the yield of regular cotton. The disadvantage of bamboo is the use of chemicals that are necessary to create a processable textile fiber. Especially when these partly toxic substances end up in the environment, this has a very negative impact on sustainability.

Fortunately, closed systems are increasingly being used, in which waste materials are reused and do not end up in nature.

Pros:

- Biodegradable, made from renewable raw materials

- Little water needed

- Little land needed

- Prevents soil erosion

- No use of pesticides and fertilizers

- Does not contribute to the plastic soup

Cons:

- Many chemicals are needed to produce a textile fiber

Cotton

A major disadvantage of conventional cotton is the enormous amount of water required for cultivation. The figures differ greatly per country, for example from “only” 4, 000 liters per kg in China to a shocking 22,000 liters per kg in India. Organic cotton is “better” than regular cotton on most fronts. No pesticides are used (better for the environment and the grower), no artificial fertilizers are used an irrigation is more efficient (less water consumption). But the yield of organic cotton compared to regular cotton is much lower, so more land is needed to produce the same amount of cotton. Both organic cotton and regular cotton contribute to soil erosion, although this is much less with organic cotton than with regular cotton. Research has shown that organic cotton, compared to regular cotton, provides:

- 46% reduced global warming potential

- 70% less acidification potential

- 26% reduced eutrophication potential (soil erosion)

- 91% less blue water consumption (water extracted from groundwater or surface water bodies)

In some models, however, regular cotton comes out better than organic cotton, purely because (much) less land is needed (about 50%) to produce the same amount. However, the general conclusion is that it is always better to opt for organic cotton, because the impact of cultivation in its entirety is lower. It is also expected that this will get even better in the future.

The pros and cons of organic and regular cotton

|

Organic Cotton |

Regular Cotton |

|

|

|

|

Biodegradable, made from renewable materials. |

Biodegradable, made from renewable materials. |

|

Low CO2 emissions and other greenhouse gases |

Low CO2 emissions and other greenhouse gases |

|

Does not contribute to plastic soup |

Does not contribute to plastic soup |

|

No use of pesticides and fertilizers |

Use of pesticides and fertilizers |

|

A lot of water is needed |

Needs a huge amount of water |

|

A huge amount of land is needed |

A lot of land is needed |

|

Many chemicals are needed to make textile fiber |

Many chemicals are needed to make textile fiber |

|

Relatively weak end product, short life span |

Relatively weak end product, short life span |

Hemp

Hemp yields about 3x as much per m2 as regular cotton, the water consumption is 3-4 times lower than with regular cotton. Just like bamboo, hemp scores a lot better on water consumption and yield than regular cotton. Less pesticides are also used, because the plant naturally suffers little from insecticides. Another advantage of hemp is that the fiber is very strong and wears less quickly than, for example, cotton. Organic hemp is still rare, but it does exist. Organic hemp plants are not fertilized with fertilizers, unlike conventional hemp. Bigger differences, however, are further down the chain, when making the fibers suitable for textile processing. With conventional hemp, quite strong chemicals are usually used in the various steps of the production process. Organic hemp uses natural and organic resources.

Pros:

- Biodegradable and made from renewable raw materials

- Hemp grows twice as fast as cotton, so it requires a lot less land.

- The hemp plant has few problems with insects, so few pesticides are needed

- Little fertilizer needed

- Prevents soil erosion

- Longer life span

Cons:

- Hemp has stiff fibers, which makes it labor-intensive to make good fabric.

- Hemp is often mixed with other substances to make it less stiff. This makes it more difficult to recycle.

Tencel

Tencel is the brand name of the fiber Lyocell. In principle, Tencel and Lyocell are the same. Tencel and Lyocell are textile fibers that are made using a chemical process from wood fibers from eucalyptus trees, but also from beech, birch, spruce and pine. The Austrian company Lenzing has launched the Tencel brand. A Lyocell fiber that is guaranteed to come from sustainably managed forests. Lyocell can also be produced in a less sustainable way, which, for example, results in deforestation, including soil erosion. But if textiles bear the Tencel brand, you can be sure that they have been produced as sustainably as possible. The wood used for the end product Tencel always comes from FSC or PEFC certified forests, where felling is balanced and the ecosystem is disturbed as little as possible. The forests are thinned out, large trees are used to make furniture, small trees are used for wood pulp for Tencel, for example. This makes Tencel a residual product of the wood industry. The chemicals needed to make Tencel fibers are used in a closed-loop system. This makes it 99% reusable. The production process is most similar to that of (bamboo) viscose, but due to the closed-loop system and the use of much less water (265 l per kg Tencel versus 600-1000 l for a kg viscose), it is a lot more environmentally friendly.

Pros:

- Biodegradable

- Absorbs 50% more moisture than cotton

- Bacterial growth is 2000 times slower than in synthetic fabrics such as polyester

- The required chemicals are used in a closed-loop system

- Tencel always comes from sustainably managed forests

Negatives:

- Lyocell does not always come from sustainably managed forests

- Production process takes a lot of energy

Polyester

In many people, the first reaction to polyester is negative. It is of course a non-natural synthetic material and the raw material for it is not renewable. Those are two big negatives. But polyester also has advantages in terms of sustainability, although you might not expect that so quickly. The production process is less intensive and more environmentally friendly than that of cotton, for example. Less chemicals are used, no land is needed and very little water is needed. In addition, polyester is extremely strong and will last a very long time. Also an important aspect of sustainability. In some models, polyester is therefore relatively high when it comes to sustainable production, it often scores higher than cotton and bamboo and in a few cases (certainly if the required amount of land is taken into account) even higher than organic cotton. But the fabric also has major disadvantages, such as the use of a non-renewable raw material, the fact that it is not biodegradable and the microplastics that are released through use and during washing.

Pros

- Very strong, hardly wears and therefore lasts a very long time

- Fewer chemicals are used in the production process than, for example, with cotton

- No land and little water is needed for production

Negatives

- Not biodegradable

- Is made from crude oil, a non-renewable resource

- Production process takes a lot of energy

- Synthetic clothing contributes to the plastic soup because microplastics are released during washing

How do I choose a sustainable diaper?

Apart from the durability of the various materials used, there is also another factor involved. To what extent can the end product be recycled? An article that can be recycled and whose raw materials can be (partly) reused scores very well on sustainability. Diapers made from a mix of materials (such as cotton with polyester or hemp/bamboo with cotton) are by definition more difficult to recycle. A diaper that is only made of one material scores more sustainability points in that respect. Although mixing with polyester, for example, does extend the lifespan considerably, which is good for the sustainability points in another area. So tough discussion!

The P for Profit

Reusable diapers at the Negenmaandenbeurs (Amsterdam) 2022

Profit is an important aspect of sustainability. The idea is that People, Planet and Profit must be in balance for sustainable development. Profit does not necessarily have to be expressed in money, knowledge and quality improvement can also be seen as profit. If profit becomes too much of a priority, People and Planet will suffer. Due to lower wages and a less environmentally friendly production process, for example. On the other hand, the profit characteristic is an essential part of a sustainable chain. The P for Profit was replaced in 2002 at the world summit on sustainable development by Prosperity (prosperity). So that, in addition to economic gain, social gain would also be included.

A good example of the importance of this third P within our own company is our participation in major fairs, such as the Negenmaandenbeurs and the We Are Pregnant fair. A large and beautifully decorated stand at such a large event is only possible if a company has sufficient financial resources. Without sufficient profit, visibility at these types of events would not be possible and the impact of your sustainable product is therefore less due to a lack of visibility.

Is one diaper more durable than the other diaper?

Unfortunately, the answer to this question is not that easy. There are so many factors that go into determining whether something is sustainable and some of them are diametrically opposed. Just look at the cultivation of cotton versus organic cotton. Is the use of land (and, for example, any resulting deforestation) a more important factor than water use? Or not? And if a diaper is made entirely of organic cotton, but it wears out after a year and is no longer usable after two years, is that better than an organic cotton diaper with polyester that might last twice as long? In fact, it comes down to determining for yourself what you consider to be important factors of sustainability. If you know that, you can determine which diapers fit more into your sustainable image and which less.

Reuse is in any case a very good choice in terms of sustainability. Use your cloth diapers as long as possible. Have your kids wear them off until they are really worn down to the thread. With an extra booster if necessary and at least a good pair of diapers, diapers often last much longer than you would think at first glance. Buying reusable cloth diapers second-hand can also be a good idea. This is possible on various second-hand sites, but keep in mind that PUL has a limited lifespan and often does not last much longer than one child. For the absorbent parts, you especially want to know how they have been washed. Diapers that have not been washed properly can cause serious skin rashes, they often wear out faster, they can smell very bad and there are sometimes absorption problems. Unfortunately, you just have to believe a seller on his or her blue eyes, because you only notice whether a diaper is dirty or really clean after using it. Washed and dried, the diapers often smell normal and only start to smell after one or more pees.

A beautiful pile of used cloth diapers

If you really want to be very safe, you can look in our second-hand section. The reusable diapers that we sell second-hand have all been tested for water resistance. If the PUL is no longer good enough, we will explicitly state this in the product text and we will only sell such a product for the materials or as a doll's diaper. The price will of course be adjusted accordingly. We can never say with certainty whether diapers have been washed really well. However, you can always contact us if something is not right and we will always solve it in an appropriate way. Second-hand items can also be returned free of charge within 14 days. That way you run little risk and you are very sustainable!

Whether you opt for new or used cloth diapers, in the end there is no such thing as the most durable reusable cloth diaper. Every diaper and every material has its advantages and disadvantages. If you want to make an extra conscious choice, simply choose a diaper that matches what you find important, whether this is material, lifespan or recyclability. New or used, all good. All reusable diapers are sustainable compared to disposable diapers, so in that respect you always make a sustainable choice with a reusable diaper.

Written by Ilka, owner Nappy's.nl